Super Gasoline and WWII

By Ken Carter

It has always puzzled me as to why the German Luftwaffe kept on using 87 Octane Aviation Gasoline while the Americans and British used 100 Octane Gasoline in their Spitfire Fighters and Americans used 130 Octane in our P-51 and other fighters.

This is a declassified article by the British Society of Chemists (Declassified in 2014)

It seems that the German and British aircraft both used 87 Octane Gasoline in the first two years of the war. While that was fairly satisfactory in the German Daimler-Benz V-12 engine, It was marginal in the British Rolls-Royce Merlin XX engine in British aircraft. It fouled the sparkplugs, caused valves to stick, And made frequent engine repair problems.

Then came lend- lease and American aircraft began to enter British service in great numbers. If British engines hated 87 Octane gasoline, American, General Motors Built, Allison 1710 engines loathed and despised it. Something had to be done!

Along came an American named Tim Palucka, a chemist for Sun Oil in their South East Texas Refinery. Never heard of him? Small wonder, very few people have. He took a French formula for enhancing the octane of gasoline and invented the “Cracking Tower” and produced 100 octane aviation Gasoline. This discovery led to great joy among our English Cousins and great distress among the Germans.

A Spitfire fueled with 100 Octane gasoline was 34 miles per hour faster at 10,000 feet. The need to replace engines went from every 500 hours of operation to every 1,000 hours. Which reduced the cost of British aircraft by 300 Pounds Sterling. Even more, when used in 4 engine bombers. The Germans couldn’t believe it when Spitfires that couldn’t catch them a year ago started shooting their ME-109 E and G models right out of the sky.

Of course, the matter had to be kept secret. If the Germans found out that it was a French Invention, They’d simply copy the original French patents. If any of you have ever wondered what they were doing in that 3-story white brick building in front of the Sun Oil Refinery on Old Highway 90, that was it. They were re-inventing gasoline. The American Allison engines improved remarkably with 100 Octane gasoline but did much better when 130 octane gasoline came along in 1944. The 130 Octane also improved the Radial Engine Bombers we produced. The Germans and Japanese never snapped to the fact that we had re-invented gasoline. Neither did our “Friends” the Russians. 100,000 Americans died in the skies over Europe. Lord only knows what that number would have been without “Super-Gasoline”. And it all was invented just a few miles west of Beaumont, TX and we never knew a thing about it.

The 2022 Walter Rosenthal Award Winner is a Club Member

In case you didn’t see this article from the May-June issue of the Vintage Ford magazine, our own Kathy Tagert won the prestigious Walter Rosenthal, which is the highest honor that the Model T Ford Club of America can bestow on a member.

Walt Rosenthal served as the first president and was always willing to lend a hand, donate a needed part or offer encouragement to newcomers.

A few words from Vic about Roger Spillers

by Vic Donnell

Roger was a business man, a soldier, a craftsman, father, and mentor to many of us. Once upon a time, he and I worked together (after hours) in my shop for several members of our club and other collectors at large. He had more restoration experience than me (and I had been at it for more than 25 years at that time), and we worked well together. After that experience, he and I continued together for another few years. He knew that I had (forever) wanted a dual cowl phaeton, Classic Car. One day, a fellow club member who hailed from Dallas told me of such a car, owned by deceased Dallas-ite, that I might be interested in. Roger and I followed several good and some useless leads but finally were able to schedule a visit to the heirs of the car. It was a 1929 Stutz, extended wheelbase, dual cowl phaeton, a monster car. The only problem was that the car had been disassembled by the owner, the parts distributed through several buildings on the property, and after a few decades, he had died without ever starting restoration or assembly. All of the chrome trim parts were missing when we tried to conduct an inventory. Roger agreed to partner with me in the purchase and we marched off to Dallas to collect the car.

The parts inventory, the collection and transport of the car, and the meticulous assembly are all interesting stories, but the skills of Roger make a more interesting story. For example, the phaeton top assemble consists of several bent wood bows and some metal hinge components. The front bow, which fastens to the windshield when the top is up, was rotted and mostly missing. Roger steam bent and fabricated a replacement bow, from white ash wood, and installed it to the top mechanism. You would swear it was original to the car. Cars of this vintage didn’t use thermostats to regulate water temperature. Thermostats had not yet been invented. Instead, the cars were equipped with shutters in front of the radiator to restrict airflow and raise the water temperature. This was called a Pines Winter Front. The Stutz had one of those with vertical blades. These blades were all twisted out of shape due to being walked on while lying on the ground. Roger took that winter front home for repair. When he brought it back, it looked like new. Detail work like that is what Roger did and enjoyed.

Together, we got the Stutz together and running, but without any top material. We determined that we didn’t want to invest any more time or money in this car and we couldn’t afford to buy the other out. So, we decided to sell it. What to do?

When I told him about the Hershey Swap meet in Pennsylvania, he decided that was the place to take it. He had never been to Hershey. So, we got the car into one piece, loaded it into one of my trailers, and planned the trip to the annual Hershey Swap Meet in Pennsylvania. What an adventure.

Roger, and Jan and I drove up to Pennsylvania pulling the trailer while Roger’s wife flew and met us along the way. We put the Stutz in the car corral of the swap meet and watched over it. It drew an unbelievable crowd, even though it was in primer and had no interior. It did however, run and drive. Roger had never been to Hershey and he couldn’t stand around and just watch after the Stutz. He just had to walk through the rest of the swap meet. When returning to where Jan and I were with the Stutz, Roger noticed people in the crowd walking the other direction talking about the Texas Stutz. He said they were amazed at the spectacle and couldn’t imagine it hadn’t sold.

Well, it did sell, to a Spaniard who was escorted by a Tex-Mex interpreter. Well, the Spaniard gave us good money and the Tex-Mex interpreter came back to Texas with us to close the deal. The car was shipped and all was good. I miss that old car.

There is a lot more to this story.

Vic Donnell

The 2nd Tech Session For Alex Gillman

by Tom Romberg

The second Tech Session at Alex Gillman’s home was a good success. The focus was on his transmission reassembly.

Attendees, while I was still there, were George Brunner, who brought not only his experience and wisdom but also a booklet on just the servicing of the transmission, Tom Romberg, Randy Brown, Wayne Mimms, who drove his souped up Touring from Cedar Park, Alex’s father, several of Alex’s friends, and our newest member, Alan.

The second activity, after George’s introduction on the subject, was cleaning of parts, sanding of rust, and inspection of parts. Spindles and bushings were miked and found to be in good shape. One of the two sets of gears were chosen as being the best. Flywheel bolt threads were chased. A review of the clutch plates was made and a sharing of another Buda shop for electrical rebuilds. An inspection of the brake drum-clutch male posts indicated a significant amount of wear which would conceivably cause a sticking to plate compression or release. A replacement will be looked for or a rehab explored. The clutch spring was tested and two were under spec pressure. Another will be ordered. Band linings were debated. A new set will be ordered.

For those that attended it was fun to enjoy the donuts, coffee, and the opportunity to see the Gillman home and yard, with the Center door showing a lot of new paint, wood repair , and assembly. We are all envious of Alex’s tools, storage of them, and his knowledge of just where tools are within the great quantity.

We all look forward to seeing the next steps.

Some Photos of the second Tech Session at Alex Gillman’s

The Model TT Truck

From Wikipedia, the free encyclopedia, by Bob Ross

The Ford Model TT is a truck made by Ford. It was based on the Ford Model T, but with a longer wheelbase, and a heavier frame and rear axle, giving it a rating of 1 short ton (0.91 t).

Production

When the first three units were produced in 1917, the Model TT was sold as a chassis with the buyer supplying a body. The price was $600. Starting in 1924, the truck was available with a factory-produced body. By 1926 the price had dropped to $325. In 1925, a hand-operated windshield wiper was added.

Military Production

In his World Encyclopedia of Military Vehicles, author Pat Ware writes that: “During World War I, the Model T was .. standardized in the “light” class. The first truck, using a long-wheelbase chassis designated Model TT, was launched in 1917. Although Ford was a pacifist, he was happy to supply the US Army with more than 12,000 of these vehicles,” and “there was no civilian production of the Model Ts between 1917 and 1918.”

Further on, Ware writes: “The Model T was widely used by the US and British armies during World War I as a staff car, ambulance, van and cargo truck, even as an artillery tractor, for which application the truck was fitted with twinned rear tires.” Many remained in service into the 1930s.

Below are the numbers of Model T trucks produced each year, not including Canadian production.

1917 – 3; 1918 – 41,105; 1919 – 70,816; 1920 – 53,787; 1921 – 64,796; 1922 – 154,039; 1923 – 246,817; 1924 – 259,118; 1925 – 306,434; 1926 – 213,914; 1927 – 74,335.

The rear axle of the TT has a worm drive and crown wheel, unlike the Model T’s crown wheel and pinion. The worm is located at the end of the drive shaft and above the crown wheel. The wheelbase of the Model TT is 125 inches (3,175 mm), compared to 100 inches (2,540 mm) for the Model T. It was often equipped with an accessory gearbox, such as the Ruckstell or Jumbo gearboxes, which allow the truck to have intermediate gears between low and high, useful for hill climbing.

The Model TT was very durable for the time, but slow when compared to other trucks. With standard gearing, a speed of not more than 15 mph was recommended, and with special gearing, a speed of not more than 22 mph was recommended. Standard worm gear ratio is 7.25:1, and special gearing gives a ratio of 5.17:1. Because of this, accessory catalogs offered items to help give the Model TT more power.

It was replaced by the Ford Model AA truck in 1928.

Tech Session at Alex Gillman’s Oma’s House

by Tom Romberg and Jim Ferguson

photos by Joe Pinnelli

On February 19 the club had what the Model A Club calls a Restoration Clinic at Alex’s Oma’s house. She had coffee and pastries and Alex has his ’21 Center Door in her garage. Bob Ross was instrumental in suggesting the clinic but wasn’t able to attend. It was fun to see and somewhat daunting to see lots of parts in boxes, a new shipment of parts, and all the rest of the project up close.

The focus of the clinic turned quickly to the engine which had obviously been cleaned, planed, and had a crank with bearing caps loosely in place.

Looking at Alex’s engine and rotating assembly, Tom checked the crank journals with a micrometer and cylinder walls with a gage and the consensus was crank, cylinders, babbitts, and pistons were all serviceable. Referring to the “Model T Ford Service” book “Taking up main bearings” and with a new shim pack we started.

We set the shims, draw cap nut down tightly lining up with cotter pin hole. Test tightness by turning engine over slowly to feel resistance. Back then no dimensional clearance or torque specs were given it was all by feel.

We had modern help with plastigauge and torque wrench to set thrust and bearing clearance.

Club attendants were Tom, Jim, Randy with a guest, Pat, George, Joe, Al, Richard and Alex with his father.We need to do this more often and we cold have a bigger crowd on tour days.

It appears as though everyone had a good time and Alex was extremely thankful for all the help and experience.

Some Photos of the Tech Session

It appears as though everyone had a good time and Alex was extremely thankful for all the help and experience.

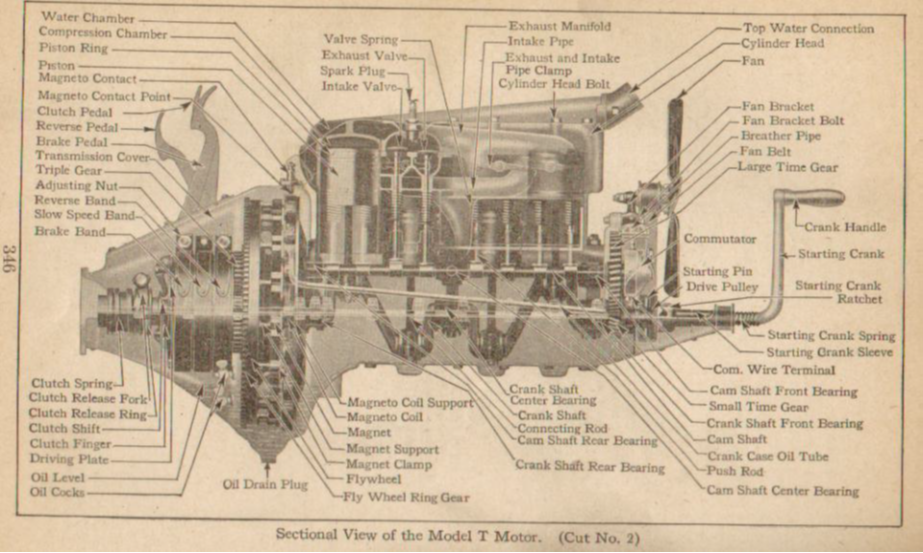

The Model T Engine

From Wikipedia, the free encyclopedia

Ok, here’s the deal, the Smithsonian Museum of History, it has many names, America’s Attic being one, has a magazine called of all things, the Smithsonian. The magazine decided to try to find the 101 most influential items out of its 137 million objects. That’s MILLION, with a “M”. Some of these items include little things like the American buffalo, the passenger pigeon, John Deere’s steel turning plow, Lewis & Clarks compass, Lincoln’s stove top hat, the Wright flyer, the Spirit of St. Louis and somewhere in the back, is the Model T Ford.

The Ford Model T used a 177 cu in (2.9 L) side valve, reverse-flow cylinder head inline 4-cylinder engine. It was primarily a gasoline engine. It produced 20 hp (14.9 kW) for a top speed of 45 mph (72 km/h). It was built in-unit with the Model T’s novel transmission (a planetary design), sharing the same lubricating oil.

The T engine was known for its simplicity, reliability, and economy. The engine remained in production for many years, and millions of units were produced. The engine design’s lifespan exceeded that of the Model T vehicle itself, with industrial, marine, and military applications extending its production run from 1908 to 1941. The T engine is on the Ward’s 10 Best Engines of the 20th Century list.

The T engine was produced continuously from September 27, 1908, through August 4, 1941, exactly 12,000 days. This makes it one of the longest engines in series production, especially considering that the specifications remained mostly unchanged for this entire duration. Its production run for the U.S. consumer market for passenger cars and pickups was shorter, being the 19 years’ production run of the Model T itself for that market (1908 to 1927). But the engine continued to be produced and sold to various consumer, industrial, military, and marine markets throughout the world until 1941.

The Model T engine was built as a gasoline engine. While not engineered specifically for multifuel ability, its simple, robust design allowed it to successfully run on a variety of combustible fuels including benzene, ethanol, or, with various available after-market attachments, kerosene. According to Ford Motor Company, the Model T had fuel economy on the order of 13–21 mpg-US

The T engine was an inline-four, with all four cylinders cast into one engine block. Such monobloc design was an uncommon practice when T production started in 1908. It lent itself to mass production, showing the Ford company’s prescient focus on design for manufacturability. The head, however, was detachable, which not only aided Ford in manufacturing but also made valve jobs (cleaning, grinding, or replacement of the poppet valves) easier. The block and head were both of cast iron.

Engine Specs

The engine’s bore was 3+3⁄4 inches (95.25 mm) and its stroke was 4 inches (101.6 mm) even, for a total displacement of 177 cu in (2.9 L). The compression ratio was 3.98 for most engines; early engines were slightly greater. This value is low by modern standards but was typical for the era, making the engine forgiving of poor-quality, low-octane fuel and minimizing cranking effort at starting.

The valvetrain was a side valve (flathead) design.

The crankshaft had 3 main bearings.

To be continued in the next newsletter.

THE SMITHSONIAN est. 1846

Ok, here’s the deal, the Smithsonian Museum of History, it has many names, America’s Attic being one, has a magazine called of all things, the Smithsonian. The magazine decided to try to find the 101 most influential items out of its 137 million objects. That’s MILLION, with a “M”. Some of these items include little things like the American buffalo, the passenger pigeon, John Deere’s steel turning plow, Lewis & Clarks compass, Lincoln’s stove top hat, the Wright flyer, the Spirit of St. Louis and somewhere in the back, is the Model T Ford.

This item was noted as; An automobile for the masses that put America in the driver’s seat. The first Ford Model T rolled out of a Detroit auto plant on October 1, 1908. Before long Henry Ford’s mass production technology would make cars more and more affordable. Prices fell from $850 in 1908 to $280 by 1925. The 1913 “touring” edition could reach speeds of 45 miles per hour with gas mileage of 13 to 24 miles per gallon. “I loved the car more than any I have ever had.” John Steinbeck said of the model T. “It understood me!”